Welcome to NZ Cylinders

Welcome to NZ Cylinders

| Aprilia, Ducati,Honda, Husqvarna, Kawasaki,KTM, Maxter,Suzuki, Yamaha, Porche, Polaris, SeaDoo, TM |

Watch us turn your problem into a joy to ride

From an "Oh No"

From an "Oh No"  To "wow"

To "wow"

OK lets go through a cylinder repair

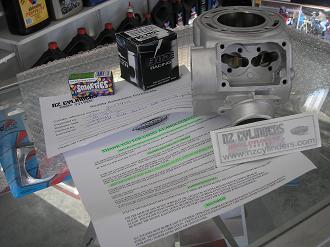

1:- login your cylinder, it's most important that you get your cylinder and all it's parts back

All cylinders and parts get their own identification number

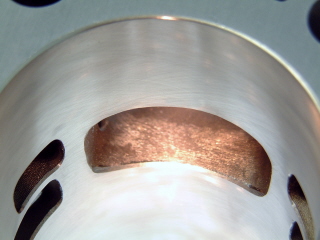

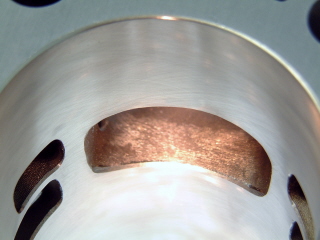

2:- Assess damage

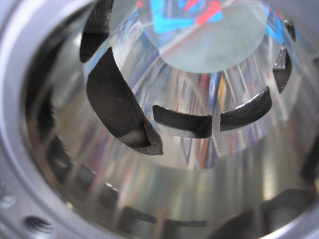

3:- Remove parts- where possible all steel parts must be removed or masked to prevent damage

4:- Bead Blast Cylinder; no oil or carbon is allowed to enter the plating room.

5:- Strip old plating; a chemical strong enough to dissolve steel and nickel is used for this.

6:- Weld cracks & scores

7:- Bore to clean weld or for a big bore piston kit.

8:- Pre-hone to remove all tool marks; if there is any imperfections left the plating will follow them; & chamfer port edges

9:- plate the cylinder with nickel silicon carbide (you can see where that brand name comes from)

10:- clean the cylinder after plating & strip the excess plating

11:- Remove excess plating from edges of ports and bottom of cylinder.

12:- bead blast for that new look

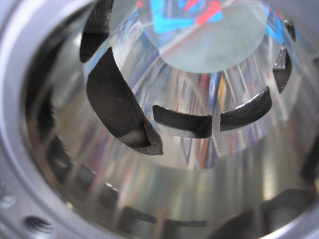

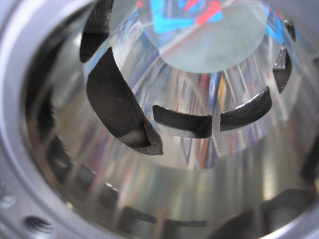

13:- hone the cylinder with diamond tooling

14:- chamfer ports, dress head gasket surface. If you send the power valves with the cylinder we can check that there is no plating build up to make them stick.

15:- Check and pack; bore is check for size specification; imperfections; chamfers for size. All parts that came with the cylinder are checked and counted (they are recorded in a database)

| ©2010 DG Engine Services

Welcome to NZ Cylinders

Welcome to NZ Cylinders  To "wow"

To "wow"